Raas Surgicals / Surgifab

At Raas, we take pride in providing high-quality disposable drapes to Hospitals and Healthcare facilities worldwide. Our products are designed with the highest standards of patient safety and comfort in mind. In this article, we would like to share a case study of how our disposable drapes have helped one of our clients enhance patient safety and comfort while saving time and resources.

Case Study: One of our clients, a large hospital in the United States, was facing challenges with their existing drapes. The drapes were not providing adequate protection from infections, and they were causing discomfort to patients during procedures. The hospital was also spending significant time and resources on washing and sterilizing reusable drapes, which was affecting their efficiency.

We introduced our disposable drapes to the hospital, and they were impressed with the quality and performance of our product. Our drapes were made of high-quality materials that provided superior protection from infections, and they were also comfortable for patients during procedures. Our disposable drapes were also easy to use and dispose of, which helped the hospital save time and resources on washing and sterilizing reusable drapes.

The hospital saw significant improvements in patient safety and comfort after switching to our disposable drapes. They also saved time and resources, which allowed them to focus on providing better care to their patients. We received positive feedback from the hospital, and they continue to use our disposable drapes to this day.

At Raas, we are committed to providing high-quality disposable drapes that help hospitals enhance patient safety and comfort while saving time and resources. Our case study with the hospital in the United States is just one example of how our products have made a positive impact on healthcare facilities worldwide. We are proud to be a valuable partner and solution-provider for hospitals, and we look forward to continuing to support their needs in the future.

Materials

The primary material used in the production of disposable surgical drapes is a non-woven fabric, typically made of spun-bonded polypropylene. Other materials such as SMS (spun-melt-spun) and laminated films are also used in the production of surgical drapes. These materials are preferred due to their low cost, excellent barrier properties, and ease of processing.

Production Process : The production of disposable surgical drapes involves several stages, including material preparation, printing, cutting, lamination, and packing. The process is highly automated and requires advanced machinery to ensure efficiency and quality control.

Material Preparation : The non-woven fabric material is prepared by melting and extruding polypropylene granules through a spinneret to produce continuous filaments. These filaments are then bonded together to form a non-woven fabric through a process known as spun-bonding. The fabric is then cut into appropriate lengths for use in the production of surgical drapes.

Cutting : The fabric is cut into appropriate sizes and shapes, depending on the surgical procedure it is intended for. Advanced cutting machines are used to ensure accuracy and precision.

Patching : In some cases, additional layers may be added to the non-woven fabric for added strength and barrier properties. This can be achieved through the process of addition patch of fabric, which involves bonding the non-woven fabric to a film layer. Advanced lamination machines are used to ensure proper bonding and strength.

Folding and Packing: The surgical drapes are then folded and packed into sterile pouches, ready for use in surgical procedures. Advanced packaging machines are used to ensure the drapes are properly sealed and sterile.

Quality Control: Strict quality control procedures are essential in the production of disposable surgical drapes to ensure they meet the highest standards of safety and performance. Quality control procedures typically involve testing the drapes for bacterial penetration resistance, linting, and tensile strength. Advanced testing machines are used to ensure accuracy and consistency.

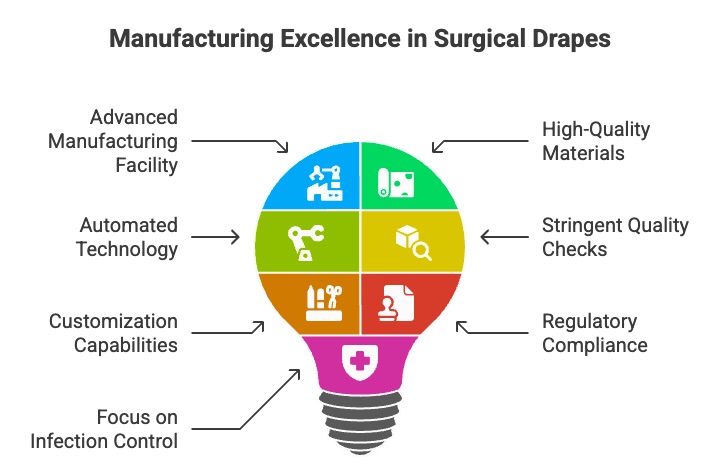

The technology used in the production of disposable surgical drapes has evolved over the years, and the current manufacturing process involves advanced machinery and materials. At Raas, we take pride in our advanced technology, which ensures that our disposable surgical drapes meet the highest standards of safety and performance, providing a sterile barrier between the surgical site and non-sterile areas.

Innovation and development are essential for staying competitive in the healthcare industry. With advancements in technology and changes in surgical procedures, there is a constant need for improved surgical drapes that meet the highest standards of safety and performance. At a surgical drape manufacturing factory, innovation and development can take several forms, including:

Research and Development (R&D): RAAS™ R&D involves conducting research to develop new materials, designs, and technologies that can improve the quality and performance of surgical drapes. This can involve collaborating with industry experts, healthcare professionals, and research institutions to identify areas for improvement and develop new solutions.

Advanced Manufacturing Technology: Advanced manufacturing technology can improve the efficiency and quality control of the production process in RAAS™. This can include advanced cutting, lamination, and packaging machines, as well as automated quality control procedures.

Continuous Improvement: Continuous improvement in RAAS™ involves implementing processes to identify areas for improvement and make ongoing changes to enhance the quality and performance of surgical drapes. This can involve regular audits of production processes, analysing customer feedback, and implementing new procedures to address identified issues.

Sustainable Manufacturing: Sustainable manufacturing in RAAS™ involves implementing environmentally friendly practices in the production of surgical drapes. This can include using recycled materials, reducing waste, and implementing energy-efficient processes.

Innovation and development in surgical drape manufacturing can result in improved performance, increased efficiency, and reduced costs, leading to greater competitiveness in the market. By investing in R&D, advanced manufacturing technology, continuous improvement, and sustainable manufacturing practices, companies can stay ahead of the curve and meet the evolving needs of healthcare professionals and patients